Data and medicine dominate the modern economy and all news channels. Behind the scenes, both depend on a third, less glamorous lifeline—water and lots of it. Data centers need enormous volumes of water to cool high-density computer loads and power fire suppression systems that protect mission-critical operations. Pharmaceutical manufacturing plants rely on water at multiple purity levels 24/7/365. These include the formulation process, rinsing, CIP/SIP, environmental control, and validated sanitation. When either sector loses access to water, the consequences are immediate and costly. Service outages, product loss, regulatory risk, and reputational damage are the result. For these reasons, the experts at NST are called on to provide water and engineering resources customized to the unique requirements of each project.

That’s why an engineered, code-compliant water storage program is no longer optional—it’s considered core infrastructure. National Storage Tank (NST) has become the preferred partner for large enterprises, EPCs, and mechanical engineering firms seeking dependable water storage at scale. From multi-million-gallon fire protection tanks for hyperscale campuses to sanitary stainless vessels integrated into cGMP workflows, NST delivers systems that perform, comply, and endure.

The Rising Demand for Reliable Water Storage across a broad range of enterprises

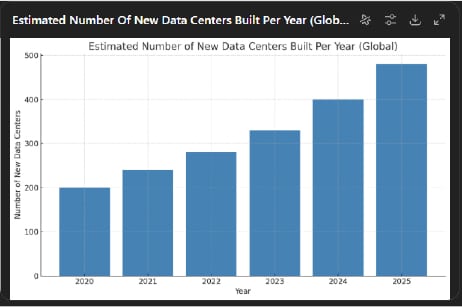

Data is hotter than ever—literally

Pharma is expanding—and tightening standards

Since 2020, new and retrofitted pharmaceutical plants have accelerated worldwide. These facilities need validated water at multiple grades (PW, WFI, and utility) for blending, cleaning, sterilization, and environmental systems. Production is unforgiving: if water availability or quality drifts, entire batches can be lost, and compliance can be jeopardized. Scalable, segregated storage—engineered for purity and traceability—keeps plants running and auditors satisfied.

The recent emphasis on US manufacturing has led major pharmaceutical manufacturers to plan to build new US facilities. These include AbbVie, Amgen, AstraZeneca, Johnson & Johnson, Eli Lilly, and Novartis, which have announced plans to spend 100s of Billions on these new US properties. Each will need massive amounts of water storage for operational purposes and fire protection. National Storage Tank is one of the largest and most experienced contractors for projects of this size, and our current workload reflects that.

The risk environment is changing

Global supply chains remain volatile. Municipal infrastructure is aging. Fire codes are evolving. Drought cycles and severe weather are now strategic considerations. Across data and pharma, executives treat water storage as a board-level risk mitigation tool, not a discretionary capital upgrade. Many states, such as California, also have mandated storage requirements before permits are issued and final inspections are complete.

Water Storage for Big Data Centers

Cooling continuity

High-availability cooling begins with dependable water. NST designs and supplies storage systems that stabilize cooling capacity under fluctuating demand and protect chilled water operations during feed supply disruptions. Bolted steel tanks with NSF-rated liners, or stainless steel tanks for higher purity needs, integrate with plate heat exchangers, cooling towers, and liquid cooling skids—ensuring the thermal plant never becomes the single point of failure.

Common use cases:

- Buffer tanks for chilled water loops and TES support

- Make-up water reserves for evaporative cooling towers

- Redundant process water storage for direct-to-chip and rear-door heat exchanger systems

- Segregated storage to support greywater reuse and sustainability targets

Fire suppression readiness

Codes require dedicated volumes, pressure, and flow for sprinklers, standpipes, and deluge systems. NST fire protection tanks—engineered to NFPA & NFPA 22 standards and local amendments—deliver fast, reliable water on demand. From 100,000-gallon vessels for edge facilities to multi-million-gallon installations for hyperscale campuses, NST systems are designed for flow assurance, seismic loading, and integration with pumps, jockey systems, and diesel backup.

Emergency preparedness and business continuity

Sustainability and stewardship

Water Storage for Pharmaceutical Manufacturing Facilities

Purity, compliance, and process reliability

In pharma, water is an ingredient, a solvent, and a sanitizer—and every use brings regulations. NST stainless steel tanks, polished to sanitary finishes and equipped with clean-in-place (CIP) and steam-in-place (SIP) provisions, support PW and WFI storage with minimal biofilm risk. With the correct inert gas blanketing, spray devices, and validated instrumentation, NST tanks help maintain integrity between purification and the point of use.

Typical applications:

- PW/WFI storage with sanitary design, orbital-welded nozzles, and ASME-coded options

- Utility water (softened/RO feed) in lined bolted steel or stainless

- Fire protection reserves sized to meet NFPA 22 and local AHJ requirements

- Process segregation using multiple tanks to isolate utilities, batching, and sanitation

Built for cGMP and inspection readiness

NST’s documentation packages support validation and audits: material traceability, weld maps (for sanitary tanks), coatings/liner data sheets, inspection reports, seismic calcs (where applicable), and O&M manuals. Where facilities fall under FDA, or EMA, robust recordkeeping and cleanable, inspectable designs translate into smoother audits and fewer surprises.

Facility integration and growth

Pharma facilities evolve quickly. NST’s modular bolted steel tanks scale to future demand; stainless sanitary tanks can be expanded or paired with additional vessels as lines are duplicated. Underground fiberglass tanks preserve surface circulation and aesthetics, while freeing floor space for reactors, skids, and utilities.

NST’s Portfolio of Engineered Water Storage Solutions

Bolted Steel Tanks (Epoxy/Glass-Fused Linings)

- Capacity: ~4,000 to 3,000,000+ gallons

- Best for: Cooling buffer, fire protection, utility water, stormwater, rainwater harvesting

- Advantages: Rapid installation, modular scalability, field serviceability, cost-effective $/gallon

- Compliance: AWWA design standards, seismic design where required

Bolted Steel Tanks

- Capacity: Custom; typically, up to 5,000,000+ gallons per tank

- Best for: Long-term, permanent installations with tight footprint or height constraints

- Advantages: Custom size structure, high design flexibility, robust for demanding sites

Stainless Steel Tanks (304/316L; Sanitary Options)

- Capacity: From 5,000 Gallons to 25,000 + gallons per tank

- Best for: PW/WFI storage, high-purity cooling loops, food-grade and pharma processes

- Advantages: Corrosion resistance, cleanability, long service life, cGMP-friendly surfaces; CIP/SIP ready

Underground Fiberglass (FRP) Tanks

- Capacity: ~5,000 to 50,000+ gallons per unit; scalable in arrays

- Best for: Space-constrained campuses, concealed fire reserves, emergency storage, stormwater

- Advantages: Corrosion-proof, lightweight, long life underground, minimal maintenance

Polyethylene (HDPE) Tanks

- Capacity: ~500 to 10,000+ gallons

- Best for: Ancillary storage, chemical dosing day tanks, small utility buffers

- Advantages: Cost-effective, fast lead times, chemical compatibility in many applications

Systems, Accessories & Controls

- Level, pressure, and temperature instrumentation; sight glasses and radar/LIDAR level

- VFD-driven pump skids, jockey pumps, and foam system integrations for fire tanks

- Seismic anchoring systems, flexible couplings, and anti-vortex inlets

- NSF/ANSI-certified liners, interior coatings, and cathodic protection where applicable

Why Major Mechanical Engineering Firms Choose NST

Large projects demand a partner who understands more than “just the tank.” Leading mechanical contractors and consulting engineers repeatedly bring their data center and pharma clients to NST because:

- Complexity is standard, not the exception.

NST’s engineering team comfortably works inside multidisciplinary environments, coordinating with process, mechanical, structural, and control engineers. Tanks aren’t islands; we ensure they fit hydraulically, structurally, and operationally. NST’s extensive experience often introduces better ways to implement and saving time and money in the process. - Performance, not just specification.

We help value-engineer solutions that hit performance and compliance targets while respecting budget and schedule. Whether that means optimizing geometry for seismic loads or right-sizing linings for water chemistry, we operate as an extension of the engineering team. - Documentation that satisfies reviewers.

From AWWAD100/NFPA22 design calculations to shop drawings, P&IDs, seismic anchoring schedules, coatings QA/QC, and sanitary weld documentation, our submittals accelerate approvals and reduce RFI cycles. - Constructability and speed to live.

Bolted steel tanks can be erected quickly with small crews and light equipment. For live campuses, this lowers disruption and improves safety. Our logistics and project management keep critical path activities on track. - Lifecycle mindset.

We think beyond commissioning and specify finishes, nozzles, and access that simplify maintenance, inspection, design, and expansion planning. Our recommendations include the total cost of ownership (TCO).

The result is fewer change orders, cleaner inspections, and tanks that do their job for decades.

Compliance, Codes, and Quality

- Fire Protection: NFPA-compliant volumes, flows, and refill strategies; integration with hydrant systems, standpipes, and foam/deluge.

- Potable & Process Water: AWWA design and NSF/ANSI-listed liners for potable service; sanitary stainless for PW/WFI.

- Seismic & Structural: Site-specific seismic design for high-risk regions, anchorage and foundation design coordination, flexible connections.

- Sanitary & cGMP: Materials traceability, surface finish documentation, CIP/SIP provisions, hygienic valves and fittings, draining considerations.

- Environmental & ESG: Support for rainwater capture, stormwater detention/retention, and graywater reuse schemes.

NST’s QA program includes incoming material verification, coating/liner inspection, leak testing protocols, and delivery of complete O&M packages for turnover.

Project Delivery: From Concept to Commissioning

- Requirements & Basis of Design

We start with load profiles, purity requirements, codes, site constraints, and schedule. Together with your mechanical team, we establish the basis of design and interface points. - Preliminary Engineering & Budgeting

Concept drawings, preliminary calcs, valve and nozzle schedules, and a Class budget. Early engagement helps you hold the line on cost and lead time. - Final Engineering & Submittals

Shop drawings, seismic/structural details, liner or sanitary spec sheets, and instrumentation lists—packaged to streamline AHJ reviews. - Fabrication & Logistics

Materials procurement, fabrication, coatings/liners, QA/QC, and shipment sequencing to support the erection plan. - Construction & Integration

Foundation coordination, erection, fit-up, hydrostatic testing, disinfection (where required), and tie-in support. - Commissioning & Closeout

Functional testing, documentation handoff, and training. Planned service programs are available to extend warranty and reduce lifecycle risk.

Total Cost of Ownership: Designing for Decades

A reliable tank isn’t just a number on a P&ID—it’s an asset with a lifecycle measured in decades. NST designs to minimize TCO:

- Durable materials and finishes aligned with your water chemistry and environment

- Access, inspection, and draining built in from day one

- Standardized parts and accessories for easy maintenance

- Smart level and condition monitoring to prevent surprises

- Modularity and scalability so the tank system grows with your campus or production line

Example Solution Paths

Hyperscale Data Center Campus

- (2) 1.5M-gallon bolted steel fire tanks, NFPA-compliant, redundant fill

- (1) 800k-gallon chilled water buffer tank with NSF liner

- Underground FRP emergency reserve array, 120k gallons total

- Level instrumentation tied to BMS, VFD pump skids, seismic anchorage

Pharmaceutical Facility

- (2) 60k-gallon 316L sanitary stainless tanks, electropolished, CIP/SIP with spray devices

- (1) 300k-gallon lined bolted steel utility water tank

- (1) 200k-gallon bolted steel fire protection tank with deluge integration

- Validated documentation package, material traceability, and FAT/SAT support

Why National Storage Tank

- Deep Sector Expertise in data center and pharmaceutical requirements

- Engineer-to-Order Capability with rapid iteration and clear documentation

- Scale and Range from sanitary stainless to multi-million-gallon bolted steel

- Seismic and Code Fluency for demanding jurisdictions

- Woman-Owned Leadership and a culture of accountability and service

- Proven Partnerships with major mechanical engineering firms who return to NST for complex, schedule-critical projects

When the risk of failure is measured in megawatts lost or batches scrapped, you need a partner who treats water storage like the mission-critical system it is.

Looking Ahead

Computer densities will rise, pharma pipelines will expand, codes will tighten, and water scarcity and infrastructure stress will persist. The organizations that thrive will be those that treat water storage as strategic infrastructure designed for resilience, sustainability, and growth.

NST is investing in advanced materials, faster installations, smarter instrumentation, and integrated reuse strategies. Our goal is simple: deliver water storage systems that quietly do their job—day after day, year after year—so your teams can focus on what they do best.

Conclusion

Data centers and pharmaceutical manufacturers cannot afford uncertainty around water. From cooling and fire protection to validated process water, the stakes are too high and the margins too thin for compromise. National Storage Tank brings the engineering depth, product range, and delivery discipline required to de-risk your project and safeguard operations for the long haul.

Whether planning a hyperscale campus, retrofitting a regional facility, or commissioning a new cGMP line, make NST your first call. Collaborate with the team that major mechanical engineering firms trust for large, complex water storage solutions.